The Definitive Guide to Inventory Management (2023) – Everything You Need to Know

Inventory is at the core of any retail business, be it online or brick & mortar. Timely arrival of inventory from suppliers, assembling & maintaining the stock, and shipping the finished products to the customer as promised is critical to the success of any business.

That’s why, as a business owner, it’s important you understand every aspect of inventory management to experience a continued growth of your bottom line.

This guide to Inventory Management will put you on that path.

Contents

What is Inventory Management?

Why is Inventory Management Important?

Inventory Accounting: A Critical Part of Inventory Management

The 7 Steps of Inventory Management Process

Inventory Management Methods & Techniques

Inventory Management Software

Automate Your Inventory Tracking & Management with SaasAnt

Inventory Management FAQs

What is the difference between EOQ and JIT?

What is Inventory Management?

Inventory management is the process of overseeing and controlling the ordering, storing, and using of components that a business needs to create a product or service. It ensures that businesses have the right amount of inventory at the right time for maximum profitability.

Inventory management involves:

Monitoring levels of stock, making sure stock is rotated properly, maintaining an up-to-date record of inventory status and managing supplier relationships.

Accurately forecasting demand by analyzing various sources of data such as sales figures, customer feedback, seasonality patterns, etc.

Striking a balance between keeping costs low (avoiding wastage) and ensuring customer satisfaction (having sufficient stock).

Good inventory management is all about implementing an effective system where businesses can improve their bottom line by reducing costs associated with unnecessary purchasing, storage fees and lost sales due to inadequate stock levels.

Why is Inventory Management Important?

Let’s take a common example.

On a bright sunny day, Carl - owner of a thriving online clothing business - wakes up to an alarming call that his latest batch of product has been delayed and so, multiple orders cannot be fulfilled.

Trying to salvage an otherwise no-point-of-return situation, Carl calls a nearby supplier and orders a new batch of finished product to be shipped ASAP, albeit at a higher price.

Just when everything seems to fall in place, the delayed batch reaches his warehouse almost at the same time as the newly ordered batch.

Now Carl has more product than he can manage, a demand to safely store the product, customers who’re unhappy with the delayed delivery and of course, a spreadsheet showing excess money spent on inventory than he originally planned.

Should he blame miscommunication? - Well, it doesn’t matter.

It’s a murky situation and it’s all thanks to ineffective inventory management.

Over the last few decades, we’ve have seen multiple corporations losing billions of dollars due to poor inventory management. Be it Walmart, Best Buy, or Nike, they’ve all seen their fair share of customer wrath resulting from unfulfilled orders and inventory challenges.

In fact, companies such as Toys R Us had lost customer trust due to ineffective inventory & customer management, leading to their demise.

And hence there’s the need to apply consistent inventory management methods & techniques so your small business does not hit rock bottom.

But before we look at these models, let’s look at some essential accounting standards applicable to all types of inventory management models.

Inventory Accounting: A Critical Part of Inventory Management

Inventory accounting is the practice of correctly assessing on-hand inventory, an invaluable asset to any business. It needs to be accurately documented in annual financial reports (including balance sheets and P&L reports) so it can be tracked and managed over time.

Without proper inventory accounting practices in place, a company's entire system of stock & inventory management could quickly become disorganized or ineffective.

While inventory accounting does appear to be simple, it becomes more intricate due to changing figures when sales are finalized or further products are bought.

It is, therefore, highly recommended to seek professional bookkeeping or accounting services when it comes to submitting any financial documents related to your inventory, as it ensures accuracy and timely submissions.

3 Main Types of Inventory

From an accounting perspective, inventory is divided into three major types in the retail industry.

Raw Material: Raw materials are the fundamental building blocks necessary for creating a finished product. They make up an integral part of business inventory. If your business uses these components to create something that can be sold to customers, it’s counted as inventory. However, when raw materials are sold directly to another business they’re considered stock.

In-progress: In-progress inventory represents all the components that you make but yet to assemble. These items, located midway through a production cycle, aren't finished goods or raw materials but do possess some degree of value. When taking accounting into consideration, in-process inventory is considered a current asset and appears on your company’s balance sheet.

Finished product: These are assembled and finished products ready for sale. Most retailers only hold finished products, ordered directly from suppliers, as it makes inventory management less complicated. It’s important for retailers to make note of finished inventory they have on hand at all times so that they can accurately assess its worth and include it as an asset in their financial records.

It’s essential to keep count of each component when it comes to inventory, be it sold or still on-hand. To ensure that financial records are accurate and up-to-date for the end of a fiscal year, you must identify both the cost associated with any product that has been sold as well as an appropriate value for the unsold items being held at closing time.

This process becomes much easier when you use an accounting automation tool which automatically reviews and syncs your sales & unsold inventory.

When the value of your goods fluctuates, your inventory figure is directly impacted, which then ultimately influences the worth of your entire business. It’s therefore critical to use modern accounting technology to streamline your inventory management & accounting practices.

The 7 Steps of Inventory Management Process

Solid inventory management commences at purchase order placement and culminates in delivery or a return/replacement transaction.

Now let's dive deeper into each component of this process.

Step 1: Placing a Purchase Order

As a new retailer, the first step is to place an order for the desired products. When creating this purchase order, two elements must be carefully considered:

When to place a purchase order

Obviously, you should exactly place an order for products to be available at a certain time and date. You can use one of the inventory management methods above to figure out this information.

When you are aware of this timeline, you can easily determine when to place a purchase order (PO). For instance, in an ideal world, if your supplier needs one week for delivery purposes, then it’d be wise to submit the PO at least seven days prior. This way, you will have ample time to make sure all items delivered meet your expectations.

However, in the real world, this is not a realistic expectation. Your vendor may take longer than your expectations at times; thus, you must use either the average lead time or remain stocked with an emergency backup in case of late deliveries.

The quantity for the order

How many products should you order in your next purchase order? Following the last example, since you know that your vendor can provide goods on a weekly basis, it’d be advantageous to buy just enough for what you're selling in that week instead of storing additional stock.

When it comes to inventory management, the fundamental concept is that having too much stock ties up your capital. Your goal should be to hold just enough inventory so you don't run out of product but not more than that.

If you're already in retail, start by looking into your past data and trends to forecast future sales. Don't let yourself become blindsided by unexpected changes or a product that falls out of fashion! For those who are new in the business, market research coupled with competitor analysis should be used as guidelines when determining how much inventory is needed for an initial purchase order.

Step 2: Receive & Check Inventory

Upon receiving the inventory, many retailers tend to neglect a quality check on the merchandise that is shipped directly to their warehouse. But if this step is skipped, it may cause returns and replacements in the future. Therefore, conducting an inspection of all products upon arrival should be top priority for every retailer.

Are they being destroyed after landing in your warehouse or is their damage a result of transport?

As you inspect the items that are delivered, it's easier to trace back any damaged goods. To determine for sure, an extensive quality control process must be done on each shipment upon arrival.

Step 3: Storage & Stocking

With potentially hundreds of different product categories in your warehouse, you'll need to think about how each should be stored thoughtfully.

Consider factors such as:

If the items must remain sealed or exposed to air,

If they can tolerate light and humidity fluctuations, and

If they move quickly off shelves or not. These details will ensure that stock is preserved effectively.

It’s essential to label each shelf and aisle in your warehouse. This will make the process of finding products easier when orders come in.

It also helps for future purposes. For example, when you expand over time and find yourself fulfilling hundreds of orders per day, having this methodical approach means you won't be searching for items during critical moments.

You can also store all slow-moving inventory in one centralized location.

As you contemplate what physical conditions will ensure your products have the longest possible shelf life, take into account any issues that may arise in the warehouse. For example, if water leakage occurs, immediately relocate all items to a more secure spot until it is addressed and eradicated.

When the warehouse is located within a store, it may merely be in the form of a backroom. In this case, concentrate on relocating products from and to that area with extra vigilance. Even minor mistakes can cause an inaccurate understanding of your stock.

Step 4: Accepting Customer Orders

For online retailers, when a customer visits your store or adds items to their marketplace cart and then places the order, you'll be instantly notified so that you can begin fulfilling it promptly.

For those selling at a physical store, utilizing a Point Of Sale (POS) system in your store can make inventory management much simpler. You must first do an initial stock count of each product and update the numbers into the system before you get started. After this, managing your products will be effortless; as the POS automatically tracks sales -increasing or decreasing stock- depending on customer orders.

B2B retailers must give close attention to their inventory management practices, especially when it comes to managing bulk orders. A website can help customers place orders easily and conveniently; alternatively, you may accept purchase orders from your clients so that you can fulfill them more efficiently.

In the past, accepting customer orders and processing them fulfillment was a tedious process involving multiple spreadsheets. However, manual inventory management is quickly becoming a thing of the past as various systems and products have been designed to automatically adjust inventories with each order. This makes it simpler for businesses to ensure their stock levels are kept up-to-date at all times.

Step 5: Order Fulfillment

Order fulfillment is different for ecommerce stores and physical stores:

In an ecommerce setting: The order-processing staff sorts products into separate containers and picks out items in the specified sequence. Generally, identical goods from multiple orders are added to the bin first.

Once all components for an individual order have been collected, a single invoice is printed reflecting that particular purchase. If you’re managing things manually, then stock levels of those items must be readjusted; however if using integrated software programs, inventory count is already adjusted when placing each new order.

For retail outlets: order fulfillment is a simple process. To complete the sale, you must process your customer's payment and/or charge their products. It’s recommended that you offer returns or replacements for a limited timeframe following the purchase.

Step 6: Shipping Orders

This step is best applicable to online stores or retail stores who also operate online.

The next step in the inventory management process is shipping the products. As per the shipping provider’s regulations, orders are shipped in distinct containers/boxes and their delivery details as well as shipping labels are affixed on the outside.

If more than one shipping partner is involved, there can be several consignments sent out during that same period of time depending on the volume of orders.

After you dispatch your items, you can use the AWB (Airway Bill) number provided by your shipping partner to monitor their progress. Depending on the Service Level Agreement (SLA) of your partner, delivery could take just a few days or up to several weeks.

Customers usually rely on you for the AWB number so that they can track their order. When the delivery partner has successfully dropped off the package, an update will be sent to you; thus marking a complete fulfillment of your order.

Step 7: Managing Returns & Replacements

For various reasons, customers may wish to send back or ask for a replacement of their item. For online purchases, many retailers offer free shipping as they enter into an agreement with the delivery provider to provide one complimentary return/ exchange service.

For customers purchasing in-store, providing them with the convenience of returning their product will maximize customer satisfaction - and when inventory is managed collectively across all stores, this should not be a problem. Offering returns from multiple locations removes yet another barrier that could prevent shoppers from making a purchase.

For each product that is returned or being replaced, you must inspect it for any damages or faults. If the item is found to be in satisfactory condition, then add it back into your inventory and adjust your count accordingly. On the other hand, if the item cannot be used again due to its defects, discard and write off from your records entirely.

Inventory Management Methods & Techniques

Now that we understand the process to improve inventory management, we also need to understand some techniques and methods that can smoothen the process even more.

Here’s an extensive article on 13 Different Inventory Management Methods & Techniques (with formulas).

It covers the followings methods:

Just-in-time Management (JIT)

Materials Requirement Planning (MRP)

Economic Order Quantity (EOQ)

Day Sales of Inventory (DSI)

Cross-docking

Perpetual Inventory Management

Minimum Order Quantity

Safety Stock Inventory

Reorder Point

Batch Tracking

Consignment Inventory

ABC Analysis

Dropshipping

Inventory Management Software

Software plays a critical role in streamlining your inventory process. Depending on the industry you’re in, you may want to employ a robust software that will work in accordance with your existing ERP or accounting system.

There are multiple software that can be deployed based on your use case. We’ve created two extensive articles on the best software for small businesses and ecommerce business.

If you’re someone who wants to build a custom inventory management system for your needs, without depending on a third party software, then the good news is that it’s possible. Here’s an extensive article on How to Create a Simple Inventory Management System.

Xero Vs QuickBooks: Which is better for Inventory Management

Most small businesses and ecommerce store owners use QuickBooks or Xero for their accounting. They’re both versatile software with a plethora of accounting options. However, both these software have their pros & cons when it comes to handling inventory.

To learn how to enter inventory into QuickBooks refer this guide.

Here’s an extensive article on Xero Vs QuickBooks for Inventory Management.

It’ll give you insights as to which software is the best for your needs.

Automate Your Inventory Tracking & Management with SaasAnt

The #1 challenge with any inventory system is the manual inputs required. These manual entries are often error-prone and a primary reason for poor inventory management.

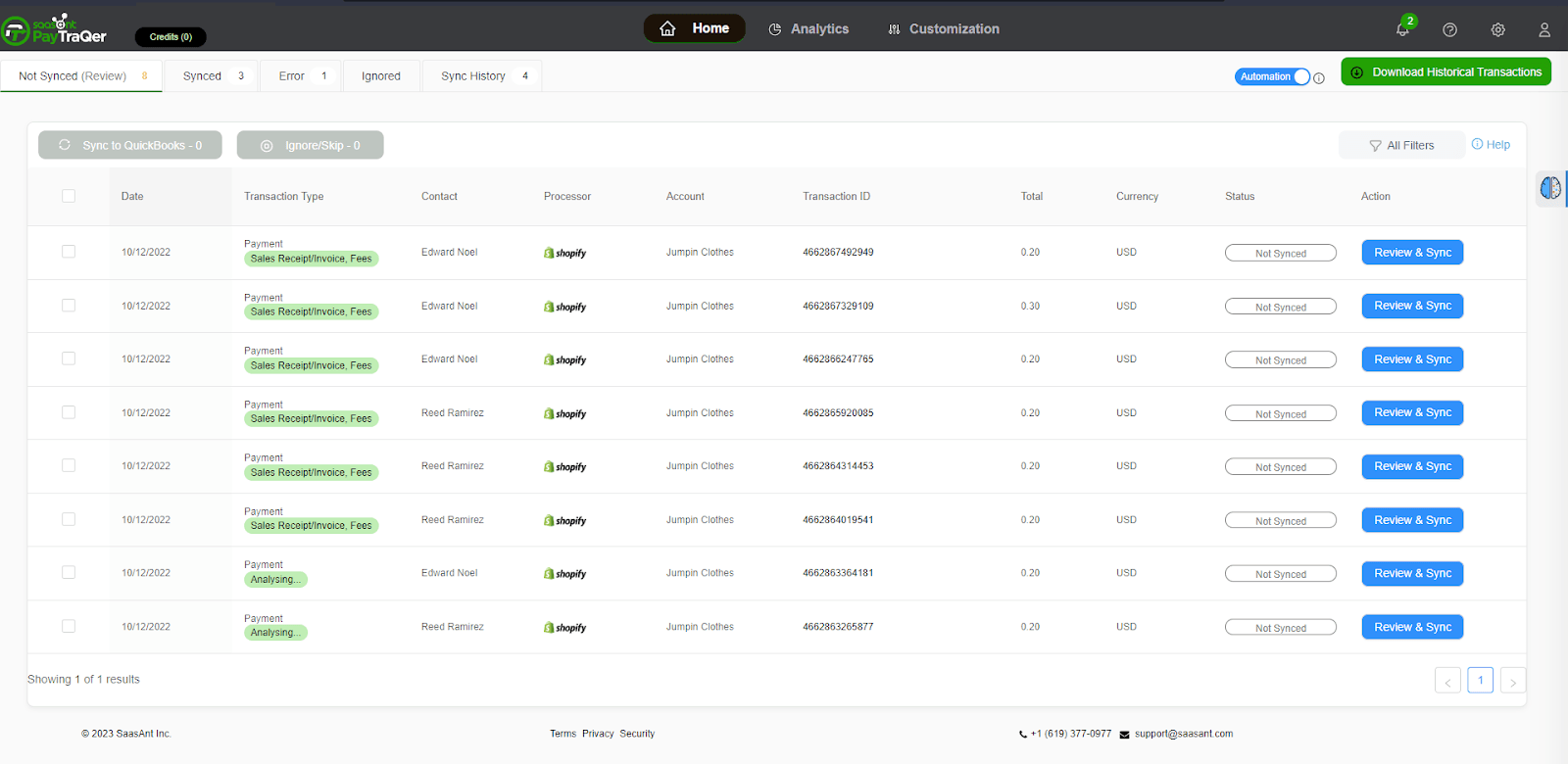

It’s best to automate some of your inventory management processes using apps such as SaasAnt Transactions and PayTraQer which update your inventory on the go without any human intervention. They work perfectly with popular accounting software such as QuickBooks and Xero.

Some of the things you can update automatically using SaasAnt are:

Supplier invoices

Sales Invoices

Inventory count

List entities

Day-to-day Transactions

Bulk import of your invoices

SaasAnt also lets you create and upload excel sheets which are updated into your accounting system. PayTraQer works perfectly for ecommerce merchants who use multiple platforms such as Shopify, WooCommerce, Amazon and more.

By automating mundane manual tasks, you can spend more time on streamlining your inventory management processes.

Try SaasAnt Transactions and PayTraQer today.

Inventory Management FAQs

What is Inventory Counting?

Inventory counting is an important process in inventory management, as it allows businesses to keep a better track of their inventory assets. It’s a systematic process which requires professionals to conduct a physical evaluation of stock to get an accurate measure of what inventory is currently available, both in terms of quantity and value. Inventory counting also provides valuable insights into the value of one’s inventory assets and helps forecast future inventory demand.

What are Common Inventory Management Challenges?

Some of the common inventory management challenge are:

Estimating Inventory

Tracking Inventory Manually

Unorganized Inventory Records

A Lack of Transparency

Handling Multiple Warehouses & Channels

Overstocking and Overselling

Lacking Insights into Inventory Data

You can learn more here: Inventory Management Challenges & Solutions.

What are the costs involved in inventory management?

Typically, there are 5 costs involved in inventory management:

Ordering Costs

Holding Costs

Spoilage Costs

Shortage Costs

Carrying Costs

How are Cogs and inventory related?

Inventory is an asset, whereas COGS (Cost of Good Sold) is one of the ways to calculate inventory that’s sold.

Cogs is calculated as follows:

Cost Of Goods Sold (COGS) = Beginning Inventory + Purchases - Ending Inventory

Here’s an extensive article on The Role of COGS in Inventory Management.

What is the difference between EOQ and JIT?

Both of them are inventory management methods. EOQ relies on large batch sizes to decrease per-unit costs whereas JIT relies on minimal batch sizes and quick lead times that reduce storage costs.

As a strategy EOQ can come with immense economies of scale but potentially high levels of stock, which would require costly storage or handling services. Likewise, JIT’s smaller orders may also result in higher purchasing expenses due to more frequent ordering.

The best inventory management system for your specific business will depend upon many variables such as size, product selection, and customer demand.